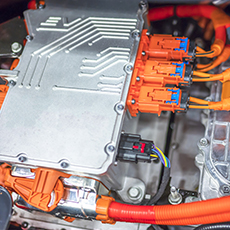

As the industry moves towards zero emission, carbon free and carbon neutral standards, GGB is ready to support our customers who are making critical components for battery electric, hybrid electric and alternate fuel cell electric vehicles. Our advanced polymer coatings and tribological surface engineering solutions are key to reducing energy used to overcome friction, which can account for >50% of losses, while providing a quiet, smooth, comfortable and safe user experience.

GGB’s wide range of materials provide excellent noise reduction, fluid compatibility and increased lifetime. Feel assured that our environmentally friendly, lead free products do more than just comply with ELV (End of Life Vehicles) and RoHS (Restriction of Hazardous Substances) regulations. Partnering with GGB early in the systems design process and selecting the right tribological materials proves to enhance overall systems performance, reduce energy losses from friction and ultimately extending battery life.

Using our lightweight, low friction materials in electric powertrain components and thermal management systems can have a positive impact for increased power density and extended battery range.

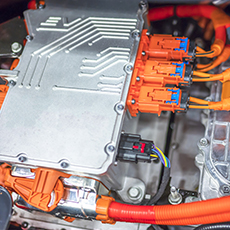

Applications for EVs

- E-Motors

- E-Powertrain

- Battery Cooling

- E-coupler/reducer

- E-Axles

- Drive by wire

- Power steering systems

- Wheel disconnect / motor disconnect systems

- Motion control, precise position control, propulsion

- Battery cooling systems

- Heat pumps / E-compressors

- Hydrogen fuel systems

- Clutches, hubs, and power transfer units

GGB Bearing and Coating Solutions for Electric Vehicles