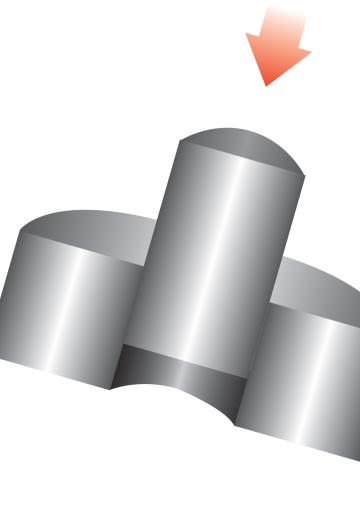

Determining force to press a sleeve bearing into its housing

- First, determine the contact surface interference pressure, p

Where:

δ = diametral interference fit

d = nominal contact surface diameter at bearing OD/housing bore interface

do = housing OD

di = bearing ID

Eo and Ei = modulii of elasticity for housing and sleeve bearing respectively

υo and υi = Poisson’s Ratios for housing and sleeve bearing respectively

- Next, calculate frictional force, F

F = p × A × μ

Where

p = calculated contact surface interference pressure

A = contact surface area of bearing / housing interface

μ = coefficient of friction at bearing / housing interface.

For GGB metal-polymer bearings, compensate for the bronze inner structure and polymer layers on the interference pressure calculation, adjustment to the ID should be made:

- For PTFE-based metal-polymer bearings, the ID of the bearing, di = dnom + 0.6 mm, where dnom = the nominal bearing ID

- For thermoplastic-based metal-polymer bearings, the ID of the bearing, di = dnom + 1.2 mm, where dnom = the nominal bearing ID

- For GGB metal-polymer bearings, the OD of the bearings can be defined by the specified GO/NOGO ring gages

The calculated value of the maximum frictional force is used to determine the capacity of the installation arbor press required to install the sleeve bearing. The maximum frictional force is based on the max interference fit, δmax = maximum bearing OD – minimum housing bore.

Estimating bearing installed ID

Another reason for calculating the contact surface interference pressure, p, is to estimate the elastic expansion of the housing due to the interference fit with the sleeve bearing and consequently estimating the installed bearing ID. This approach is especially helpful when the housing has a fairly thin cross section and/or has a low modulus of elasticity relative to the bearing material (for example, a metal sleeve bearing pressed into a plastic housing).

Where:

Δd = estimated elastic expansion of housing bore

p = calculated contact surface pressure, calculate both pmax and pmin

d = nominal contact surface diameter at bearing OD/housing bore interface

Eo = housing modulus of elasticity

do = housing OD

The simplified approach found above will provide an estimate of the housing elastic expansion from which the min/max installed ID can be calculated. However, this approach is not meant as a substitute for Finite Element Analysis or other advanced design programs.