Frequent Maintenance

Greased bearings require regular re-lubrication, increasing downtime, and maintenance costs.

Contamination Risks

Grease can attract dust, dirt, and debris, which causes wear and can compromise system reliability.

Environmental Concerns

Improper disposal or leakage of grease can harm the environment, adding regulatory and sustainability challenges.

Reduced Efficiency

Grease can break down under extreme temperatures or heavy loads, causing increased friction, higher energy consumption, and potentially premature failure.

Operational Inconsistencies

Varying lubrication conditions can result in inconsistent performance, reducing precision and reliability.

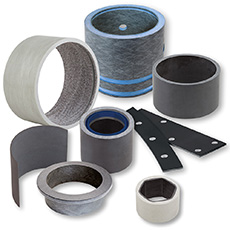

Benefits of Removing Grease in a System

Eliminating lubrication/grease from your system can bring significant advantages, making your operations more efficient, cost-effective, and environmentally friendly:

Lower Maintenance

Self-lubricating bearings reduce the need for regular lubrication, leading to minimal maintenance and reduced downtime.

Cleaner Operation

Without the need for grease, systems remain clean, minimizing the risk of contamination and improving component life.

Cost Savings

Eliminating grease reduces the costs associated with purchasing, storing, and applying lubricants. Additionally, it removes the need for lubrication systems and related components, further reducing costs.

Simplified Design

Systems can be designed more simply when lubrication is not required. This can lead to fewer components, reduced complexity, and potentially smaller and lighter designs.

Increased Reliability

Grease-free systems maintain consistent performance even in extreme conditions, offering higher durability and dependability.

Reduced Friction

Self-lubricating bearings are designed with sliding layers that are resistant to wear, helping maintain smooth surfaces over time and reducing the generation of friction from wear particles.

Environmentally Friendly

Grease-free solutions eliminate the environmental risks associated with grease disposal and leakage, promoting sustainability.

Longer Component Life

By removing grease, you prevent the buildup of contaminants, resulting in less wear and extending the lifespan of critical components.