Bearing Application Requirements

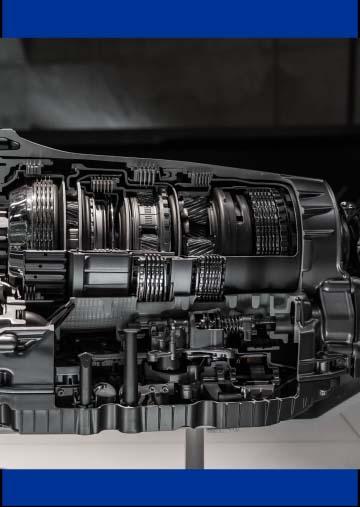

Planetary gearboxes are used in a wide range of applications, including construction machines, test rigs, plant construction and other types of special machines and vehicles. These gearboxes are especially effective due to their strong load-bearing capacity, torsion rigidity and when space and weight are among the chief concerns.

One concern however is the fundamental nature of planetary gearbox vibration.

A planetary gearbox manufacturer was using needle bearings in several areas of the gearbox, including the output shaft, central gear and as a mounting for the other rotating bearings. These bearings created noise, vibration and excess friction that lowered performance, and their moving parts increased maintenance requirements.

Seeking a replacement for their expensive, poorly performing needle bearings, the gearbox manufacturer turned to GGB for a plain bearing solution.

GGB Self-lubricating Plain Bearing Solutions

DP4® is a lead free, self-lubricating metal-polymer bearing that consists of a strong steel backing, a porous bronze inner structure and a polymer resin lining. DP4® low-friction plain bearing features a thin wall design for space and weight reductions compared to needle bearings. DP4 low friction bearings are generally free from stick slip and are able to operate without external lubrication.

The compact bearing design of DP4® allowed the manufacturer to reduce the size of its housings. In addition, the larger contact surface area compared to needle bearings provided higher load bearing capacity, better impact resistance and improved performance.

By partnering with the GGB applications engineering team, the manufacturer was able to successfully replace their needle bearings and achieve lower friction, less maintenance and reduced size and weight.

GGB Self-Lubricating Bushings - Benefits

DP4® self-lubricating plain bearing provides the following benefits in planetary gearbox applications: