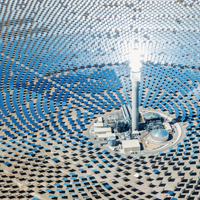

As the solar industry continues to grow, equipment manufacturers are challenged with sourcing a reliable plug and play solution that can withstand harsh environments with intense UV rays at a low cost. GGB understands these challenges and has bearing solutions designed to meet these needs.

Specialized Solutions for High Performance

As each solar facilities needs are different, the demand for specialized solutions that can withstand extended UV exposure, and abrasive contaminants common in windy environments are most important for solar power generation.

Solar Tracker Applications

- Slew Drive

- Linear Actuator

- Shock Absorber/Damping Cylinder

- Pivot Points

Reliable Tribology for Solar Trackers

The new GGB EP®15 engineered plastics solution was developed specifically for use in photovoltaic solar power generation facilities with tracking solar panels. The EP®15 material features excellent UV and abrasion resistance in addition to a low coefficient of friction and lightweight design. All EP Series products are compliant with EVL, WEEE and RoHS specifications. GGB also offers a range of fiber reinforced composite bearings and TriboShield® Polymer Coatings for solar power production.

EP®15 Offers:

- UV resistant bearings

- Good operating performance in dry, oil-lubricated and grease-lubricated applications

- Corrosion resistant in humid/saline environments

- Self-lubricating

- Abrasion resistant

- Low coefficient of friction

- Lightweight

- Smooth movement and tracking

- Unlimited dimensions and design features

- Compliant to ELV, WEEE and RoHS specifications

GGB's DP4® low friction bushings offer good wear and low friction performance over a wide range of loads, speeds and temperatures in dry running conditions. These features make DP4® material a great solution for solar applications.

GGB's HPMB® offers an environmentally friendly material that requires no lubrication with excellent corrosion resistance and low wear rate making it a reliable material for solar tracker applications.

Advantages of GGB Tribological Materials

Low Friction, High Wear Resistance

Low coefficients of friction eliminate the need for lubrication while reducing wear and extending service life

Maintenance-Free

Ideal for applications requiring long service life without regular maintenance or operating conditions with little or no lubrication

Lower System Cost

Reduce shaft costs by eliminating the need for hardening and machining grease paths. Compact, one-piece construction provides space and weight savings and simplifies assembly

Environmental

Greaseless, lead-free solutions comply with increasingly stringent environmental regulations such as the RoHS directive for electrical and electronic equipment

GGB Bearing and Coating Solutions for Solar Applications

Partner with our Experts

Partner with our Application Engineers to reduce or eliminate unexpected downtime and increase time between regular maintenance operations to increase service life and improve overall system performance.

Our experts are ready to collaborate on your specific challenge to find the right solution to achieve cost savings, longer service life, increased performance and weight reduction.