Markets we serve

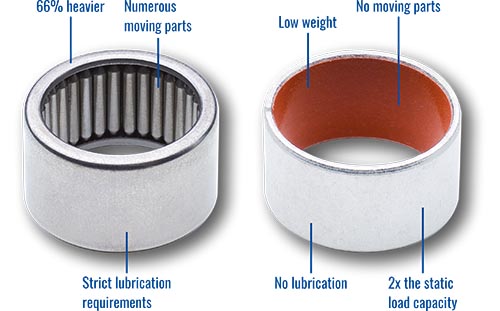

GGB’s advanced surface solutions are driving industries forward, powering thousands of critical applications worldwide every day. Our mission is to deliver reliable, maintenance-free solutions that enhance performance and longevity—no matter the application or environment. With a focus on innovation and engineering excellence, we are committed to shaping the future of motion with cutting-edge materials that meet the most demanding challenges.